Description

Walk-in Emission Chamber for Automotive Interior

| Model: Chamber for Automotive Interior | LY1022-H12 | LY1022-H24 | LY1022-H35 | |||||

| Nominal Volume (L)(m3)★ | 12(1±2%) | 24(1±2%) | 35(1±2%) | |||||

| Internal Dimension (m) |

W | 3000 | 4000 | 5000 | ||||

| D | 2000 | 3000 | 3500 | |||||

| H | 2000 | 2000 | 2000 | |||||

| External Dimension (m) |

W | 4000 | 5000 | 5200 | ||||

| D | 2200 | 3200 | 4460 | |||||

| H | 2400 | 2400 | 2400 | |||||

| Character | Temperature Range | RT+5~90 ℃(>90 ℃ Custmoized) | ||||||

| Temperature Fluctuation | ≤65℃ | ≤ ±0.5 ℃ | ||||||

| ≤90℃ | ≤ ±0.8 ℃ | |||||||

| Temperature Uniformity | ≤65℃ | ≤ ±1.2 ℃ | ||||||

| ≤90℃ | ≤ ±1.8 ℃ | |||||||

| Heating Rate | ≤65℃ | ≥1.5 ℃/min | ||||||

| ≤90℃ | ≥1.0 ℃/min | |||||||

| Air Exchange Rate | 0.1~3 t/h(Customized) | |||||||

| Sealing | Gas Leakage Less Than Capacity * 5 ‰ m³/ min | |||||||

| Background Concentration mg/m3 | Formaldehyde:≤0.02;Acetaldehyde:≤0.01;Toluene≤0.02;Ethylbenzene≤0.02;Xylene≤0.02;Styrene≤0.002;TVOC≤0.02; | |||||||

| Ventilation Fan | High Pressure Scroll Blower | |||||||

| Temperature Controlled Air Circulation Fan | Centrifugal Fan | |||||||

| Gas Exchange Flow Meter | Electronic Flowmeter | |||||||

| Purification Module | 4×4×1 Sets | 4×4×2 Sets | ||||||

| Temperature Control Method | Electric Heating, Thyristor Load Regulation Module, Forced Hot Air Circulation | |||||||

| Observation Window | 330×450 mm(W×H),1 pcs | |||||||

| Material | Shell | Prefabricated Board, Cold Rolled Steel 0.8mm Surface Electrostatic Spraying,White | ||||||

| Inner Cabin | SUS304 Mirror Stainless Steel 0.8mm with Floor Stainless Steel 1.2mm | |||||||

| Thermal Insulation | High Temperature Resistant Material + Polyurethane Composite,Thickness 100mm | |||||||

| Sealing | Silicon Gel(Food Grade)、PTFE | |||||||

| Operation Control | Monitor | 7-inch color touch screen,Resolution 800×480,Remote Control (Optional) | ||||||

| Monitoring Project | Temperature, Flow, Running Time,Fault Record | |||||||

| Control Method | Temperature Control: Proportional, Integral, Differential (P.I.D); System Control:PLC+HMI |

|||||||

| Resolution | Temperature:0.1 ℃ | |||||||

| Communication Interface | USB-A,1 pcs; USB-B,1 pcs; RS232,1 pcs; RS485, 1 pcs; RJ-45 1 pcs(Optional) | |||||||

| Storage and Record Function | RAM;U Disk;SD Card | |||||||

| Filter Replacement Cycle | >8000 h | |||||||

| Floor Bearing | 500 kg/m2 | |||||||

| Power | AC380(1±10%)V (50±0.5)Hz Three-phase Four-wire+Ground Wire Protection | |||||||

| Installed Capacity(Kw) | 18 | 22 | 28 | |||||

| Noise(dB) | ≤65 | ≤65 | ≤68 | |||||

| System Protection | Overcurrent Protection; Over Temperature Protection; Motor Overcurrent Protection; Motor Overheat Protection; Power Supply Phase, Phase Sequence Protection, etc. | |||||||

| Ambient Temperature | 0~35℃ | |||||||

★ Does not include shape protrusions

Remarks: Special sizes can be customized

International Standards:

| Standard No. | Item |

| GB18580-2001 | Formaldehyde Emission of Manmade Board and Its Products |

| GB18584-2001 | Indoor Decorating and Renovating Materials Limits of Harmful Substances in Wooden Furniture |

| GB18587-2001 | Indoor Decorating and Renovating Materials Releasing limitation of Harmful Substances from Carpet,Carpet Pad and Carpet Adhesive |

| ASTM D6007-02 | Standard Test Methods for Determination of Formaldehyde Concentration in Gases Released from Wood Products with Small Scale Environmental Chamber |

| ENV717-1 | Environmental Chamber Method for Measurement of Formaldehyde Emission of Manmade Board |

| EN13419-1 | Determination of VOCs Release quantity of Building products Chapter One The Method for Releasing and Testing the Environmental Chamber |

| HJ 571-2010 | Technical Requirements for Environmental Labeling Manmade Board and Its Products |

| HJ 566-2010 | Technical Requirements for Environmental Labeling Manmade Board and Its Products |

| VDA 270 | Odour |

| VDA 275 | Formaldehyde |

| VDA 276 | VOC, SVOC Test Chamber |

| VDA 277 | VOC Headspace |

| VDA 278 | VOC, SVOC Direct desorption |

| ISO | 12219 series |

ISO 12219-2:

Interior air of road vehicles — Part 2: Screening method for the determination of the emissions of volatile organic compounds from vehicle interior parts and materials — Bag method

,JASO_M902-2007(Japanese Automobile):

Road vehicles – Interior parts and materials-Measurement method of diffused volatile organic compounds

NES M0402-2005:

VOC Test Method of Cabin Parts

HJ/T 400-2007:

Determination of volatile organic compounds and carbonyl compounds in cabin of vehicles

TSM 0508G 2009:

Determination of organic volatiles in non-metallic materials of automotive interiors by thermal analysis

0094Z-T0A-0000:

Honda DWG No. 0094Z-T0A-0000 – VOC Test method: VOC Test methods specification for interior parts. emission test – bag method

TS-BD-003:

Determination of Volatile Organic Compounds from Vehicle Interior Parts —-Tedlar Bag Method

Reference Standards

| Standard No. | Item |

| ASTM D5116-97 | Standard Guide for Determination of Organic Release from Interior Materials and Products with Small Scale Environmental Chamber |

| ASTM D6330-98 | Standard Operation for Determination of VOCs (Excluding Formaldehyde) Release from Wooden Board with Small Environmental Chamber under Specified Test Conditions |

| ASTM D6670-01 | Standard Operation for Determination of VOCs Release from Interior Materials and Products with Full Scale Environmental Chamber |

| ASTM E1333-96 | Standard Test Methods for Determination of Formaldehyde Concentration and Release Rate in Gases Released from Wood Products with Large Scale Environmental Chamber |

VIAQ Requirements:

China:

HJ/T 400-07 December 2007

“Determination of volatile organic compounds and carbonyl compounds in cabin of vehicles”

GB/T 27630-2011, 01 March 2012

“Guideline for air quality assessment of passenger car”

Korea:

Automobile Management Act Article 33-3; 18 Dec. 2012;

Ministry of Land, Infrastructure and Transportation Notification No.2007-539,(5 June 2007)

“Newly Manufactured Vehicle Indoor Air Quality Management Standard”

Japan:

Japanese Automobile Manufacturers Association Guideline

“Voluntary Approach to Vehicle Cabin VOC Reduction”

JASO Z 125

“Road Vehicles-Interior-Measurement Method of Diffused Volatile Organic Compunds (VOC)”

ISO

ISO 12219-1:2012

“Interior air of road vehicle –Part 1: Whole vehicle test chamber-Specification and method

for the determination of volatile organic compounds in cabin interiors”

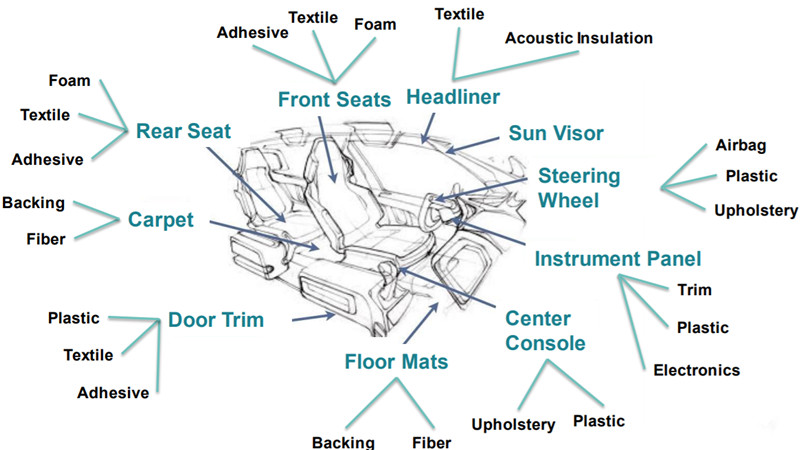

Automotive Interior Materials and Components

Application:

VOC Emission Test of Automotive Interior Parts

Aging Treatment of Tedlar Bags

Study On The Release of Gaseous Pollutants in Materials

Aging Treatment of Materials and Accessories

Odor Test

Technical Specification:

Built-in Purification Unit With Self-cleaning Function

Purification Unit Can Be Used Continuously For More Than One Year

Purification Unit Quick Replacement Design

SCR Intelligent Load Regulation, Energy saving

Comprehensive Background Concentration Control Technology

Automatic Temperature Balance And Recording

Automatic Recording Of Pressure And Flow

Modular Design And Easy Maintenance

Environmental Indicators:

Energy-saving Design, Green and Environmental Protection

Operating Power as Low as 2~5kw

Noise is Less Than 65 Decibels